PCBs for Telecom Applications

The implementation of fifth-generation (5G) technology is currently in progress, driven by the ever-increasing demands of IoT, AI, and high-resolution content. These advancements necessitate higher speeds and expanded bandwidth. In the telecom sector, we recognize challenges related to signal integrity, bandwidth optimization, and cybersecurity.

Below, you will find a selection of applications we offer, all designed to elevate speed, reliability, and cybersecurity within the telecom industry. Our focus is on shaping a connected future that meets the evolving needs of this dynamic sector.

- Antennas: PCBs for distributed radio signals. Demands are typically controlled layouts, rugged constructions and thorough material selection.

- Distribution systems: PCBs for high-speed switches, opto-electrical conversion, RF amplifiers, rugged power supplies and lightning protection. Demands are typically heat management, signal integrity and high speed.

- Microwave links: PCBs for distributed radio signals. Demands are typically controlled layouts, rugged constructions and thorough material selection.

We are an ISO 9001:2015 certified PCB supplier that can support your most intricate telecom requirements and RF circuit board designs.

Give us a try for your Telecom needs!

Radio Frequency and Microwave Printed Circuit Boards for Telecom

Radio frequency (RF) and microwave printed circuit boards (PCBs) can handle higher frequencies compared to other circuits. Both circuits are crucial elements in different professional and commercial products such as wireless communication devices, including satellites. With higher frequencies in the mix, the PCB design becomes more complex.

Millennium Circuits Limited experts can help engineer and develop RF PCB solutions to fit your application requirements and budget while maintaining top-tier quality controls and tight lead times. One of our main focuses is high-frequency PCB laminates, so you can trust our specialization in mechanical, electrical and thermal PCB characteristics.

PCBs for RF and Microwave

Printed circuit boards are already complex pieces of technology that combine mixed and digital-signal solutions. The design of the circuit board and its layout become even more complicated with the additions of radio frequencies and microwaves:

- Low-frequency signal: Includes frequencies up to 50 MHz for traditional analog components.

- Radio frequency signal: Ranges from 50 MHz to 1 GHz for AM/FM transmission.

- Microwave signal: Has frequencies above 1 GHz up to 30 GHz to communicate high bandwidth signals.

The normal frequency range of an RF is between 500 MHz and 2 GHz. However, most circuit board designs above 100 MHz are RF PCBs. Anything more than 2 GHz is a microwave frequency.

RF and microwave PCBs differ from one another, as well as a standard circuit. RF printed circuit boards operate with a high-frequency analog signal, which can be anywhere in between the minimum and maximum limits. Both radio frequency and microwave PCBs work on a frequency by passing signals within a specific band. Pass filters transmit signals within the band of interest while filtering out anything that’s outside the frequency range.

For customers with a tight turn time for a new product launch that requires a complex board, MCL provides technical expertise form prototype through production increasing speed to market by 19.8%. Get pricing and leads times.

How PCBs Are Used in Telecom

Telecom is essential for modern communications and will only continue to grow in importance as technology advances. PCBs used for telecom communications are special because they function reliably in hostile environments. Because of the challenging environments satellite PCBs must withstand, the material is a critical consideration in the PCB design and layout. The PCB materials need to last the life of the satellite, both for those that are in space and on Earth.

One major concern of telecom PCBs is outgassing, which is where gas gets trapped inside a solid — like a PCB. Circuit laminates can be porous and contain trapped gas from the manufacturing process or the curing laminate process. In high-vacuum environments like space, this gas can release. Therefore, the RF PCB material used for your telecom must have low outgassing properties.

Telecom PCBs operate under vacuum conditions and some may also have to withstand high-voltage corona fields and high dielectric breakdown voltage. Circuit materials must be considered accordingly.

Challenges for RF and Microwave Telecom PCBs

Challenges in RF and microwave PCBs can range from impedance matching and bleeding prevention to outgassing and minimizing weight. Other challenges include:

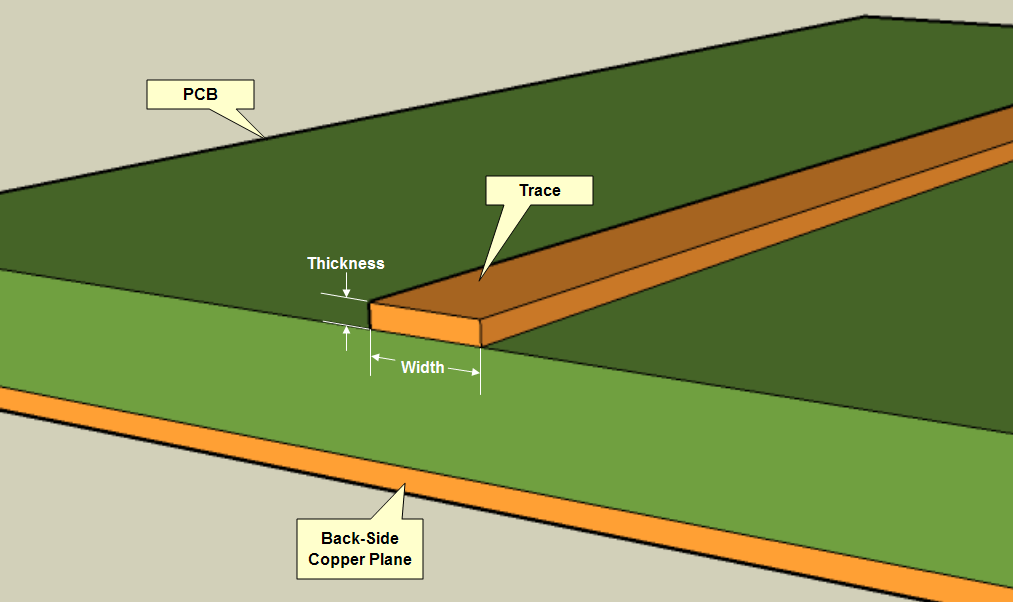

- Difficult to design: If your telecom PCB has multiple layers, different components need to be kept separate, like RF or digital parts and low-level analog. This helps to decrease issues during assembly. RF and microwave PCBs require multiple layers of design, with the top including a power stage and radio frequency signal lines. The board will also require a ground layer under any component that has RF and microwave signals.

- Noise: Radio frequency and microwave signals are sensitive to noise and more susceptible to a range of noise types compared to standard PCBs. You must mitigate signal noise, ringing and reflection as much as possible. Different types of noises can include white, pink or band limited, as well as thermal, shot, phase, flicker and avalanche noise.

- Wide temperature range: Swings in temperature levels are another concern to take into consideration. Altering temperatures within a satellite can change a printed circuit board’s material characteristics. Looking at the temperature coefficient of a dielectric constant data sheet is helpful for comparing a range of board materials and how suitable they are for telecom applications. RF microwave telecom PCBs must be able to dissipate heat well, especially in confined areas within the spacecraft. Consider the PCBs thermal conductivity to understand how the material dissipates heat in space.

- Reliability: Minimizing weight is another PCB telecom concern that relates to the growing use of circuit boards with multiple layers and increased RF and microwave circuitry density. The reliability of plated through holes (PTHs) for interconnections between layers is a concern when operating in the temperature cycling and temperature extremes in space.

Get a Free Quick Quote.

Design Considerations for RF and Microwave PCBs

For correct manufacturing and processing, RF printed circuit boards require standard and specialty equipment such as plasma etch machinery. This form of technology can maintain quality with little deviation in the through holes. Laser direct imaging (LDI) is another crucial form of technology used for RF PCBs. With an LDI backing, your board can maintain a tight trace width and front-to-back registration.

One of the biggest challenges with RF and microwave PCB designs with high-frequency laminates is sensitive signals. Other design considerations include:

- Microwave and radio frequency signals are more sensitive to noise, the system will require great care to minimize ringing, noise and reflections.

- Ground planes underneath the signal will make it easier for return signals to take the path of least inductance.

- Make sure you prioritize impedance matching because as microwave and radio frequencies increase, tolerance decreases. You will need to make fixes during the transmission stage and while sending signals to the receiver.

- The design of your microwave or RF board should guide the return path and prevent bleeding of the return signal.

- To decrease characteristic impedance that can occur on transmission lines, a bend radius that’s three times larger or more than the width of the center conductor is necessary.

Laminate materials add a layer of safety to your equipment by differing conduction, convection and radiation. In PCBs where high frequencies are used, thermal management is a crucial consideration. High-frequency PCB laminates have a range of characteristics including:

- Coefficient of thermal expansion

- Dielectric constant

- Flexibility for conformal

- Smoother copper surface

- Thermal conductivity

- Thickness

As you’re researching the right high-frequency laminate for your RF or microwave PCB, consider these different characteristics and understand how to combine them into a single solution.

Our Capabilities

Our professionals can help you better understand high-frequency laminates while meeting RF and microwave PCB requirements. By partnering with a leading RF and microwave PCB supplier, you can avoid potential hazards. We go through all the basics and detailed considerations to ensure you receive a solution that delivers optimal performance. We check the PCBs thermal conductivity and confirm it also has a low dissipation to reduce circuit insertion losses.

Several other capabilities we offer include:

- 35:1 drill aspect ratio

- Buried/bling vias and micro vias

- Controlled impedance

- Fast turnaround times

- Production and prototype quantities

We are an ISO 9001:2015 certified PCB supplier that can support your most intricate telecom requirements and RF circuit board designs.

How We Can Support Your RF and Microwave PCBs for Telecom

Contact a Millennium Circuits Limited representative online to learn how we can support your requirements for radio frequency and microwave telecom printed circuit boards. You can also read more about our RF microwave solutions today.